research area

Fermentation Physiology and Performance

The loss of productivity in large-scale bioprocesses can often be related to physiological changes in the production host. This research area aims to elucidate the physiological response of a production organism to the environmental conditions encountered during a fermentation process and develop superior cell factories and bioprocesses. Gerd Seibold’s group combines genetically encoded sensors for metabolites and signaling molecules with high-throughput methods to analyze adaptations of bacteria when up- and down-scaling fermentations. This knowledge is the basis to engineer production organisms adapted to the conditions in a large-scale bioprocess.

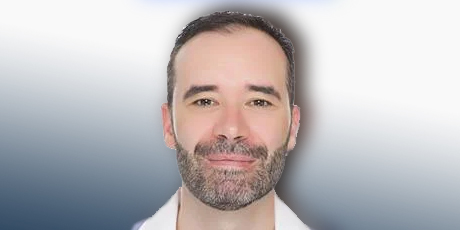

José Luis Martinez’s group Yeast Biotechnology and Fermentation follows a different approach towards superior production organisms: exploring and exploiting the natural biodiversity and developing bioprocesses with novel cell factories. These are naturally better adapted to the respective fermentation process due to their robustness, less demanding process conditions, and a wider range of possible feedstocks. This research is closely connected with Fermentation Scale-up and Scale-down and with the Automation and High-Throughput micro-Fermentation Unit of DTU Bioengineering’s Fermentation Core.